Every job site has a silent saboteur.

It isn’t a bad operator. It isn’t a worn hydraulic hose.

It’s contamination creeping into your fuel supply.

And the damage starts long before an engine sputters, alarms flash, or a generator refuses to start. By the time the symptoms show, your equipment has already absorbed weeks – or months – of slow, expensive harm.

Contamination Doesn’t Announce Itself

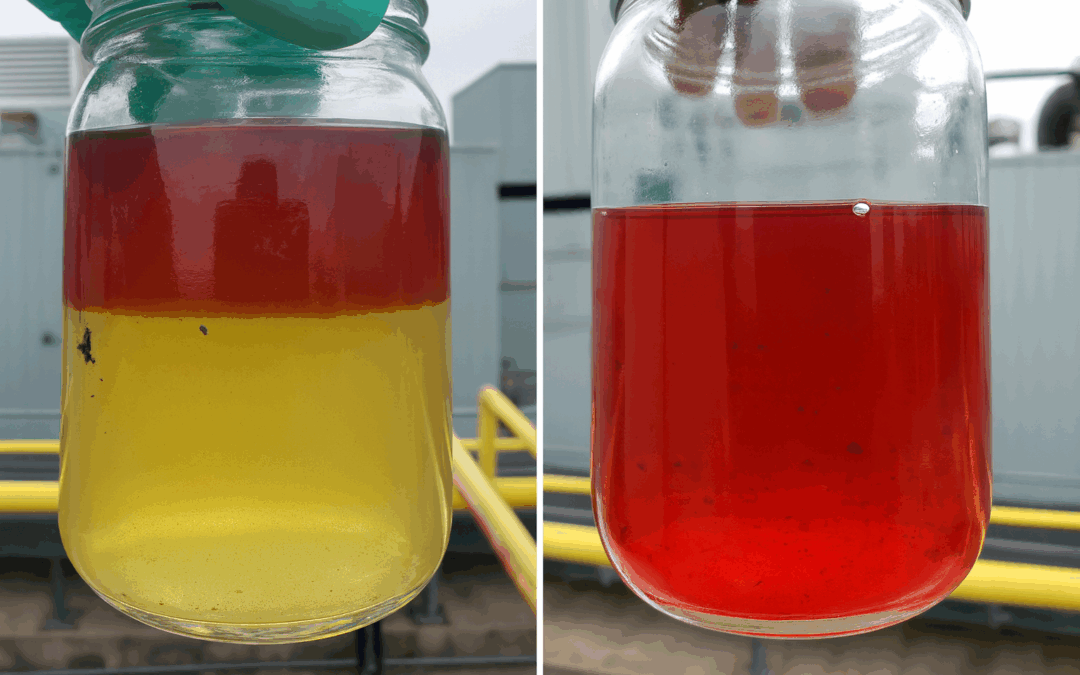

Fuel can look “clean” to the naked eye and still be loaded with microscopic problems. Diesel is especially vulnerable because it’s stored in tanks, transported through hoses, and exposed to changing temperatures—each step creating opportunities for debris, moisture, and microbial growth to get in.

The early stages of contamination are invisible. There’s no smell, no color change, no obvious indicator. Meanwhile, inside your equipment, the clock is ticking.

The First Thing It Attacks? Your Fuel System

Before an operator notices a thing, contamination has already started moving through the components that protect your engine:

•Clogged Fliters

Filters absorb the initial hit.

Even slight water content or particulate matter shortens filter life dramatically.

Many operations don’t catch this because filters are replaced on schedule—not based on condition—so they never see the premature wear.

•Injector Damage

Diesel injectors are engineered with microscopic tolerances.

A handful of abrasive particles is enough to alter spray patterns, reduce atomization, and force the engine to compensate with higher fuel consumption.

This isn’t an overnight failure. It’s a slow drift toward inefficiency, which most crews chalk up to “old equipment” or “a heavy day on the job.”

•Water: the Hidden Threat

Water enters fuel through condensation, loose caps, aging tanks, or sloppy delivery.

Tiny amounts create:

-

Rust inside tanks

-

Corrosion along the fuel path

-

Perfect breeding conditions for microbial contamination (“diesel algae”)

By the time the engine misfires? The colony has already taken hold.

Contamination Eats Money Long Before It Causes Breakdowns

Downtime is only the final chapter.

The real financial damage shows up earlier as:

-

Higher fuel burn

-

Reduced power output

-

More frequent filter changes

-

Shorter injector life

-

Inconsistent starts on generators

These are all losses you pay for, even if the equipment stays running.

Most operators don’t trace these costs back to fuel because contamination hides well and spreads slowly. The machine “runs,” so it gets overlooked.

The Worst Stage: When Contamination Becomes Normal

Many sites unknowingly adjust around contaminated fuel. They:

-

Over-idle equipment to prevent hard restarts

-

Replace filters more often

-

Accept sluggish engines as part of the job

-

Run generators with reduced efficiency

These behaviors become habit, and the contamination issue continues unchecked.

How to Keep Contamination Out of Your Fleet

Preventing damage is far cheaper than repairing it. Here’s what actually makes a difference:

1. Clean, Verified Fuel Delivery

Fuel is only as clean as the source.

Trusted delivery partners should:

-

Maintain sealed transport tanks

-

Test for particulate and water content

-

Follow proper hose and nozzle sanitation

-

Keep logs of fuel quality at the rack and at delivery

If they can’t show you how they protect your fuel, they’re not protecting your equipment either.

2. Maintain Your Storage Tanks

Above-ground and job-site tanks need:

-

Regular water checks

-

Visual inspections for rust and condensation

-

Bottom-sampling every 3–6 months

-

Correct venting to reduce moisture

3. Use fuel Polishing

If contamination is already present, polishing removes:

-

Water

-

Sludge

-

Microbial growth

-

Foreign particulates

Restoring fuel quality can save thousands in equipment repairs and injector replacements.

•Train Operators to Detect Early signs

Not the dramatic signs—the subtle ones:

-

Filters clogging faster

-

Generators taking longer to stabilize

-

Equipment requiring more throttle

-

Diesel that “looks cloudy” in cold weather

-

Fuel that smells unusually sour

Early detection saves machines.

A Clean Tank Today Prevents a $20,000 Repair Tomorrow

Fuel contamination rarely appears as a single catastrophic event.

It’s a slow, quiet process that eats efficiency and kills components over time.

Your fleet shouldn’t suffer because of something you can’t see.

If you’re running diesel equipment, generators, or job-site tanks across Texas or Utah, we can help you keep the fuel clean and the equipment healthy—before contamination turns into a costly surprise.

If you’re dependent on clean, reliable fuel for your job-site or project, count a fuel partner you can trust.

Anytime Fuel Pros delivers efficiency, cost savings, and reliable service—right to your job site.

📞 Call us today to schedule your first delivery or request a custom quote.

Recent Comments